Machining Parts

Our high-precision CNC turned parts are of exceptional quality and are widely used in the automotive, home appliance, and electronics industries.

Machining is a multi-step process involving cutting, milling, drilling, and thread tapping, primarily using various rod-shaped materials. A machining center is typically equipped with specialized cutters to accurately perform processes such as outer shaping, drilling, threading, groove cutting, vertical cutting, and knurling. This machining process is ideal for products that require high precision or complex shapes, enabling the creation of intricate parts. Key features of CNC machining parts include:

■ High-Precision Processing

CNC machining offer controlled precision suitable for parts that require strict dimensional tolerances, enhancing product consistency.

■ Complex Shape Manufacturing

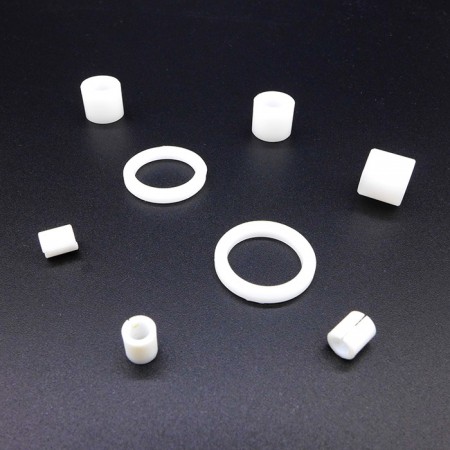

With its multi-axis processing capability, CNC machining can perform a variety of complex cuts, including turning, drilling, tapping, and thread turning. This versatility meets diverse structural requirements and enables the creation of shapes such as circles, external and internal diameters, threads, and grooves.

■ Material Versatility

Lathe parts can be made from a variety of metals, such as steel, aluminum, copper, stainless steel and plastics, making them applicable across various industries.

■ High Surface Finish

Machining processing provides a high level of surface smoothness, suitable for parts requiring surface treatment, thereby reducing the need for post-processing.

■ Flexibility and Customization

Production can be flexibly adjusted to meet the quantity requirements of customers, accommodating diverse needs.

Was Sheng has advanced complex multi-axis sliding head CNC, fixed head complex cutting-milling CNC, twin spindle turret CNC and CAM operated lathe. Manufacture range from Ø 2mm to Ø 46mm, max length to 300mm. Our specialized machining operations will satisfy your demands for customized products.

Couplings

Their primary function is to securely link two elements and transmit power or signals, widely...

Spacers

Spacers are usually in hex, round (straight or diamond knurled), or square form according to various...

Inserts

Inserts are essential for reinforcing hole strength, enabling plastic structures to endure...

Bushings

This product is primarily used to reduce friction, support bearings, or provide additional...

Precision Shafts

This product is primarily designed for use with bearings, rotating shafts, and motor spindles,...

Dowel Pins

The primary purpose of Dowel Pin is to enable quick positioning and secure part assembly, enhancing...

Customized CNC Machining Parts

To increase production efficiency while maintaining precision, we typically produce semi-finished...

Special or Customized Materials

We specialize in CNC machining and offer precision cutting services for non-metal materials,...

Our high-precision CNC turned parts are of exceptional quality and are widely used in the automotive, home appliance, and electronics industries. | Aluminium Components & Machining Parts Manufacturing | WAS SHENG

Located in Taiwan since 1985, WAS SHENG ENTERPRISE CO., LTD. has been an industrial components manufacturer. Their main manufacturing components, include Machining Parts, brass metal components, steel metal machining components, stamping components, cold forging components and aluminium extrusion components, which are ISO and RoHS certified with all levels of PPAP, IMDS and COC documentation.

Was Sheng was established in 1985. As a one-stop manufacturer, our core value is professional, conveniently and problem solver. Based on our customer support from worldwide, we operation with integrity, pragmatic and reliable attitude providing the best service and product. Combine international market trend with 30 years manufacture experience, we are proficient in CNC machining, stamping and cold forging parts, our specialist reply instantly from design to produce. By the way, standoff, insert and pin are our famous products.

WAS SHENG has been offering customers precision forging and machining industrial products, both with high-quality manufacturing process and 35 years of experience, WAS SHENG ensures each customer's demands are met.