Stamping Parts

Stamping Process—The Optimal Solution for Efficient Production of Precision Components

Stamping is a processing technique that uses press power in conjunction with mold design (including upper and lower molds) to cut, bend, and shape the sheet metal. This process includes various methods such as shearing, bending, forming, and deep drawing and suitable for materials like cold-rolled steel, stainless steel plate, and hot-dip galvanized steel plate.

By placing the sheet metal between molds and applying pressure, the material can be cut and shaped to meet specific customer requirements. Stamping can be automated, enabling the mass production of parts with consistent shapes and dimensions, thereby increasing production efficiency and saving cost. The resulting products are high in strength and structurally stable.

However, due to the complexity of mold design, the flexibility of stamped part designs is limited, making this process more suitable for the mass production of fixed-shape components.

Eyelets

Eyelets—Small Yet Essential, Adding Durability and Functionality to Your Products.These...

Retaining rings

Retaining rings are essential fastening components designed to maintain the stability of assemblies...

Internal / External Toothed Lock Washers

The toothed washer is a highly effective anti-loosening solution designed to enhance the stability...

Speed & Push Nuts

Push nuts and speed nuts are cost-efficient, time-saving fasteners designed for quick assembly...

Clips / Wing Nuts / Cage Nuts

Clips are ideal for securing and supporting components, widely used in the automotive, home...

Spring Lock Washers / Spring Pins

Spring washers, with their elastic design, effectively prevent bolts and nuts from loosening,...

Washers

Washers are typically installed beneath the head of screws, bolts, or nuts to distribute load...

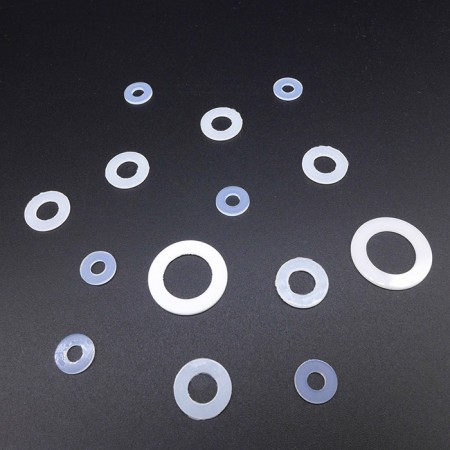

Nylon Washers

Nylon washers are widely used in various industries, including machinery manufacturing, electronic...

Customized Stamping Parts

Was Sheng has varies stamping production line that can satisfy customer’s request professionally...

Stamping Process—The Optimal Solution for Efficient Production of Precision Components | Aluminium Components & Machining Parts Manufacturing | WAS SHENG

Located in Taiwan since 1985, WAS SHENG ENTERPRISE CO., LTD. has been an industrial components manufacturer. Their main manufacturing components, include Stamping Parts, brass metal components, steel metal machining components, stamping components, cold forging components and aluminium extrusion components, which are ISO and RoHS certified with all levels of PPAP, IMDS and COC documentation.

Was Sheng was established in 1985. As a one-stop manufacturer, our core value is professional, conveniently and problem solver. Based on our customer support from worldwide, we operation with integrity, pragmatic and reliable attitude providing the best service and product. Combine international market trend with 30 years manufacture experience, we are proficient in CNC machining, stamping and cold forging parts, our specialist reply instantly from design to produce. By the way, standoff, insert and pin are our famous products.

WAS SHENG has been offering customers precision forging and machining industrial products, both with high-quality manufacturing process and 35 years of experience, WAS SHENG ensures each customer's demands are met.