Was Sheng Precision Machined & Stamped Parts Exhibit Potential to Enter Tier 1 Supply Chain

Always Ready for the Better

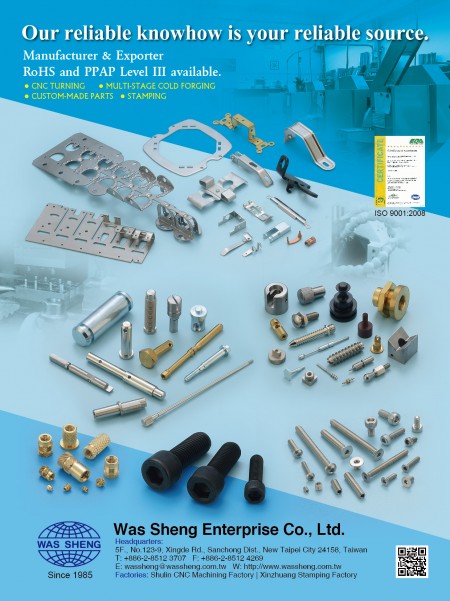

Following the NTD100 million sales record in precision parts, Was Sheng Enterprise Co., Ltd. currently offers precision machined parts (accounting for 60% of total revenue), stamped parts & screws (18% each), and other industrial products (4%). President and founder Jason Hsu said, “Reputation is very important for business. Establishing the mission statement of a company, making effort to do it, and creating characteristics enables the company to maintain competitive edge in such a fast-changing market.” Today, Was Sheng is equivalent to the title of a professional precision machined parts manufacturer and has been regularly cooperating with customers in more than 20 countries in Europe, Asia, Africa, and Americas, which helps the company keep steady growth.

All the aforesaid excellent results have a lot to do with the critical character of Was Sheng, as President Hsu has not only the knowledge of metal properties and manufacturing in machine and hardware areas, but also has experience in the studies of metallic cold forging and machining, heat treatment, and electroplating. In addition to the role as the president, he also plays important roles in private/national universities in Taiwan and China as a professor teaching business management.

Superior R&D Capability For Any Product Range

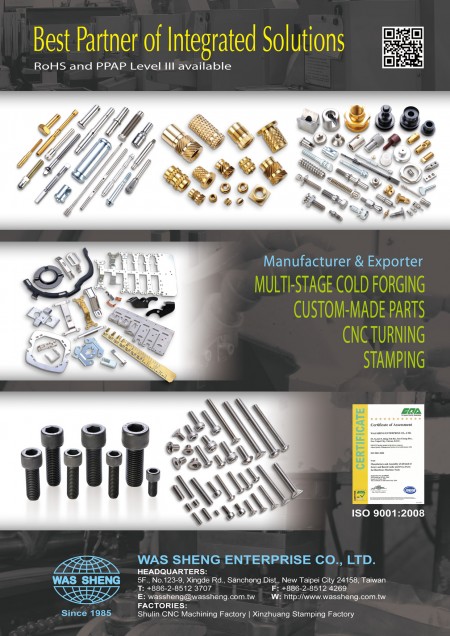

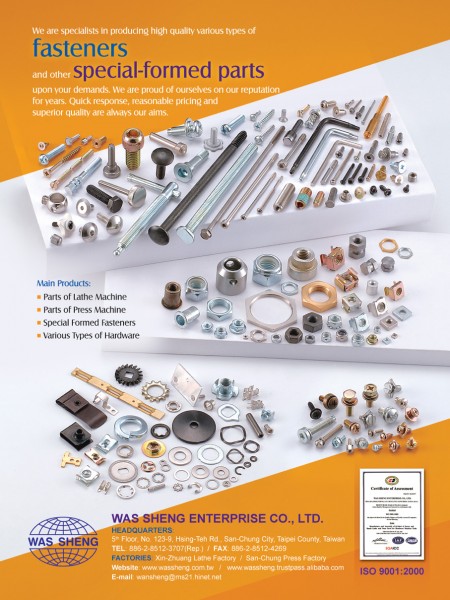

ISO 9001:2008 certified Was Sheng supplies products in steel, alloy steel, stainless steel, brass, copper, phosphor bronze, aluminum, Ti-alloy, POM, and other materials to DIN / ASTM / JIS / RoHS specifications. Was Sheng has strong manufacturing ability and develops products which are not standard. Was Sheng also has strong R&D capability and the products are widely used in automotive, motorcycles, electronics, household appliances, buildings, and machinery applications.

Accurate Market Deployment & Diverse Marketing Strategies

Most of Was Sheng's customers are local distributors, retailers, and end users. Owing to the proximity and similar cultural backgrounds, Was Sheng established trade relationship with Southeast Asia for years and has gained many good customers. Was Sheng has specialists handling this business, who regularly visit or contact customers in order to get a clear picture of their current operations and demands that may appear. President Hsu said, "Demands for diversified products in small volumes and short lead time are characteristics for the market'. As a result, Was Sheng has created a flexible manufacturing system to satisfy the requirements of customers." With the increasing importance of Chinese and Indian markets, the ability to flexibly adjusting capacity within the required lead time of customers has been the key point to Was Sheng's success. Considering the significant demand growth in Southeast Asia, President Hsu is planning to invest more resources in operating this market.

Was Sheng oftentimes promotes itself via print advertisements and online e-commerce platforms and is considering promoting in e-magazines to broaden its customer base. President Hsu said, "Every enterprise operates in different ways, so the sales networks may be also different. Understanding the strength and weakness of the company before selecting the best way to achieving the most effective development is the wisest thing to do." Our aim is to establish direct cooperation with global leading companies in the future and to strengthen the ability of its staff and the quality of products to elevate its competitive edge.

- Our Advertisement

Was Sheng Precision Machined & Stamped Parts Exhibit Potential to Enter Tier 1 Supply Chain | Brass & Steel Metal Components Manufacturing | WAS SHENG

Located in Taiwan since 1985, WAS SHENG ENTERPRISE CO., LTD. has been an industrial components manufacturer. Their main manufacturing components, include brass metal components, steel metal machining components, stamping components, cold forging components and aluminium extrusion components, which are ISO and RoHS certified with all levels of PPAP, IMDS and COC documentation.

WAS SHENG has 40 years of experience in CNC machining, milling, multi-stage cold forging, progressive stamping and customized fasteners. Combine international market trend with 30 years manufacture experience, we are proficient in CNC machining, stamping and cold forging parts, our specialist reply instantly from design to produce. By the way, standoff, insert and pin are our famous products.

WAS SHENG has been offering customers precision forging and machining industrial products, both with high-quality manufacturing process and 35 years of experience, WAS SHENG ensures each customer's demands are met.