Leading Supplier in North America- Was Sheng Keeps Changing to Face Challenges

Was Sheng Enterprise Co., Ltd was founded in 1985, mainly exports products to North America, European Union and Southeast Asia. The products sold to North America are various precision customized parts, such like electronics, home appliances and automotive components. Machined parts, cold forged parts, shoulder screws, sleeves, insert nuts were stably delivered to customers in continuous basis.

Manufacturers in Taiwan used to mass produce industrial fasteners at low unit prices. The entry barrier is low however it can be easily replaced, making companies to suffer from fierce competition and low profit. Accordingly, Was Sheng has devoted to industry upgrade and new customer development in recent years. President Jason Hsu said confidently, “Most of the automotive parts we supply are ready-to-use and buyers do not need to do any secondary treatment. Such one stop shopping service is much preferred by customers. We forecast great growth in our profit and market share in North America as we have already established long term reciprocal trust with customers.”

Jason added, “Demands from North America are mostly related to the automotive industry. Therefore PPAP paperwork is oftentimes required. The requirements in North America are not as strict as in the European Union but the market is very competitive. In fact, all buyers want is high quality with low cost. Was Sheng must supply products with stable quality, attentive service and quick delivery in order to compete with competitors. Our strength is during R&D stage, we would test and run different manufacturing methods. We aim to generate high capacity, reduce costs and then create profit. North America is a big market and customers differ a lot from each other. Comparing to other countries, it will take longer to achieve successful communication and business.”

North America is the biggest market for Taiwanese automotive fastener exporters. Our sales volume is related to car industry in North America. In year 2016 U.S. car market experienced a recession in March and later showed a stable growth in April. Such growth will definitely result positive effects in fastener supply chain if car market growth in the U.S. keeps growing. A number of interest rate increased by U.S. Federal Reserve will stimulate the economic recovery, this will result also robust growth in the housing market. The average number of new construction will maintain at least 1 million units. As the inventories are low, construction demands such like self-drilling screws, rivets, large bolts, wood screws are expected to grow continuously.

Slowdown in global economy resulted profit decline to Was Sheng. Jason immediately set a new short-term plan to accept urgent or low volume orders for achieving sales target this year. In the long term, continuous development of new customers is still necessary. After that, higher sales volume can be reached. Jason also said, “In the future Was Sheng will focus on automotive fasteners sales in North America. The top priority to do is to reinforce employee training and increase employee’s sensitiveness to product features. Currently, most customers strictly require very low defect rate or zero defect. Other than inspection equipment upgrade, we will also introduce sophisticated optical sorting machines to ensure high quality. Hopefully these new quality policies will increase our market share in North America.

One of our main strategies in the future is to focus on automotive parts; the requirements are stricter than electronics components and home appliance parts. All car makers have different standards, especially regulations on surface coating are very specific. If possible, we always want to supply fasteners, which are ready-to-use so customers can simplify their post-treatments. To reinforce our competitiveness, we have no choice but to learn all other special electroplating technologies which we have never learned in the past.” President Jason Hsu is doing all he can do to change the company. In such a recession in fastener industry, President Jason believes he can lead his employees to the next milestone.

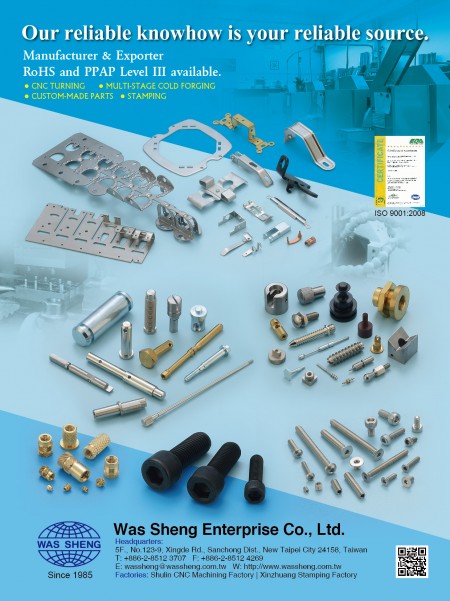

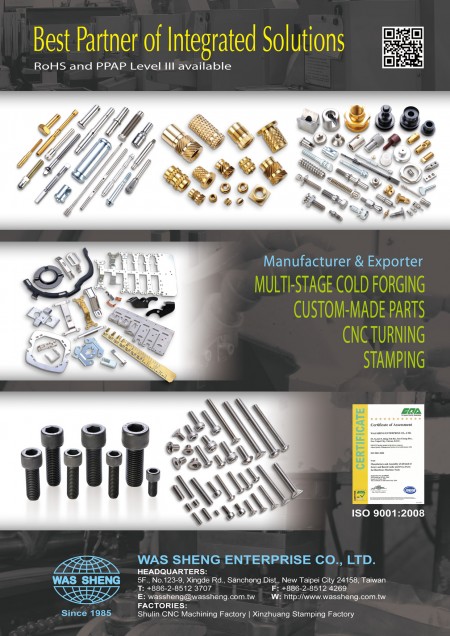

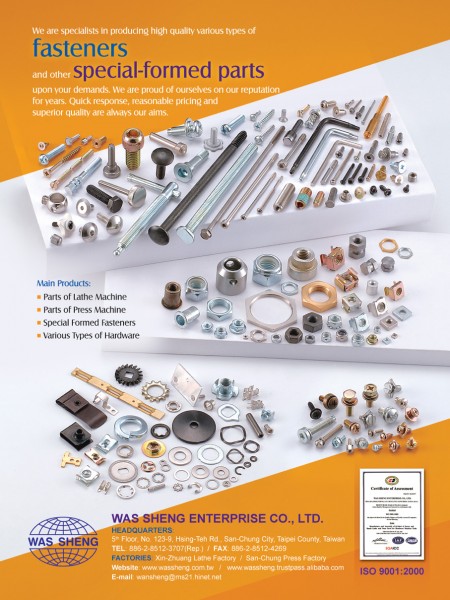

- Our Advertisement

Leading Supplier in North America- Was Sheng Keeps Changing to Face Challenges | Brass & Steel Metal Components Manufacturing | WAS SHENG

Located in Taiwan since 1985, WAS SHENG ENTERPRISE CO., LTD. has been an industrial components manufacturer. Their main manufacturing components, include brass metal components, steel metal machining components, stamping components, cold forging components and aluminium extrusion components, which are ISO and RoHS certified with all levels of PPAP, IMDS and COC documentation.

WAS SHENG has 40 years of experience in CNC machining, milling, multi-stage cold forging, progressive stamping and customized fasteners. Combine international market trend with 30 years manufacture experience, we are proficient in CNC machining, stamping and cold forging parts, our specialist reply instantly from design to produce. By the way, standoff, insert and pin are our famous products.

WAS SHENG has been offering customers precision forging and machining industrial products, both with high-quality manufacturing process and 35 years of experience, WAS SHENG ensures each customer's demands are met.