Was Sheng Enterprise- The Unbeatable on the Market

Established over 30 years ago, Was Sheng Enterprise Co., Ltd. has the ability to offer steady supply of machined parts, cold forged parts, shoulder screws, sleeves, inserts, precision axles, antenna holders, stamped parts, etc. Was Sheng’s major markets are located in the USA (purchasing mainly precision custom-made electronics, home appliances, automotive parts), the EU and Southeast Asia. The Western Europe countries mainly purchase highly engineered customized products, while Eastern Europe countries in the EU mainly purchase standard parts to public norms. As for the Southeast Asian market, the demand is comparatively even. Precision customized products and standard parts to DIN & JIS are mainly what they demand. According to Was Sheng’s revenue in 2016, 39% out of the revenue came from Americas, 35% from Europe and 22% from Asia.

Was Sheng Has Solutions To New Policies Of The United States

Since the inauguration of U.S. president Trump this year, the global economy has been unsteady and uncertain. According to Trump's newly proposed economic policies, he will invest a lot in expanding the construction of the domestic infrastructure. It is actually a good thing for the fastener industry, as the existence of more construction projects means higher fastener demand. However, it seems that Trump will adopt protective trade measures against U.S. competing countries, which implies that fair bilateral trade is likely to be substituted for free multilateral trade. Trump also promotes those U.S. manufacturers moved to other countries in the past decades should move back to the U.S., which will "Make America Great Again."

Was Sheng currently has many quality and long-term American customers. However Trump's new policies will definitely result some major influences. In order to deal with such changes in the market, Was Sheng has figured out solutions which include: increasing production capacity to satisfy urgent demands, reducing the production cost and create advantages in order to compete with US domestic manufacturers, reinforcing employees' expertise and saving time spent on repeatedly answering customers' calls and emails through offering quick and precise service. In addition to the solutions above, Was Sheng will also expand more marketing resources into its development in emerging markets. Multi-market expansion will prevent Was Sheng's global expansion strategy from being influenced by certain policies of a single country.

Getting Stronger To Face Challenges Ahead

It's noted that the dumping of low-cost fasteners from China and India in recent years has resulted in price cutting competition on the market. Accordingly, in order to ensure good product quality and stand out in a crowd, Was Sheng always has strict requirements on quality. It not only offers regular training programs to its QC staff, but also makes continuous improvement on its inspection facilities through purchasing more multifunctional optical sorting machines for reducing the defective rates of products and satisfying customers’ needs. With changes in overall market and continuous development of new technologies, human resources certainly must be innovated and hardware & software both have to be updated!

In addition to customized automotive and industrial parts, Was Sheng is also going towards the development of high value added aerospace fasteners through improving its expertise and technology and its final goal is to expand the product portfolio to micro fasteners for medical use.

Over the past two years, global economic recession did not seem to recover. Was Sheng's total fastener sales showed a slight drop compared to previous records. Nevertheless, General Manager Jason Hsu encourages employees to focus on manufacturing procedures, technical innovation, sourcing of distributors. It is critical for employees to dedicate themselves to transformation and grow up with the company, making simultaneous advancement in both quality and quantity. We believe that only through adjusting abilities to the best conditions then the company will continue to grow and progress in the fluctuating and ever-changing market.

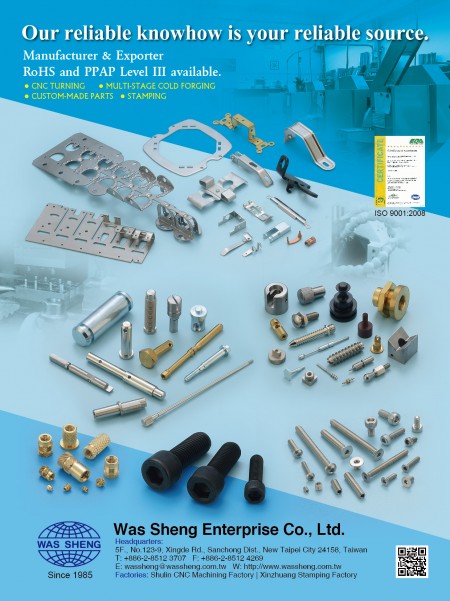

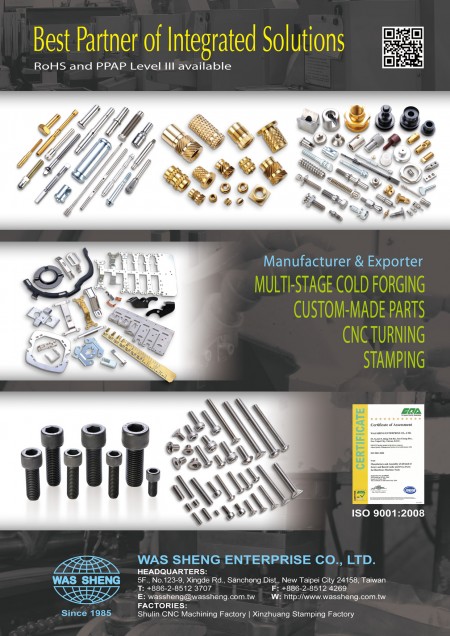

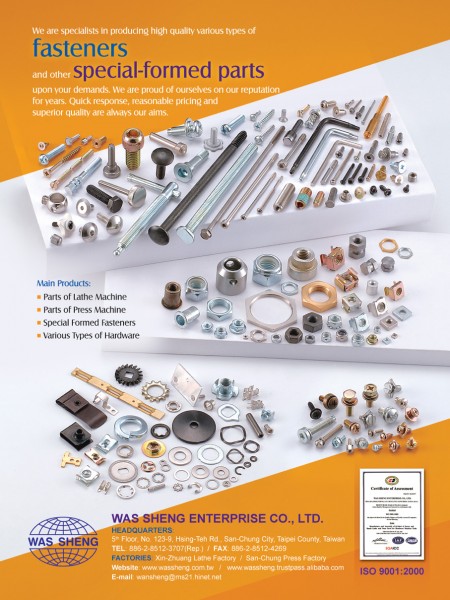

- Our Advertisement

Was Sheng Enterprise- The Unbeatable on the Market | Brass & Steel Metal Components Manufacturing | WAS SHENG

Located in Taiwan since 1985, WAS SHENG ENTERPRISE CO., LTD. has been an industrial components manufacturer. Their main manufacturing components, include brass metal components, steel metal machining components, stamping components, cold forging components and aluminium extrusion components, which are ISO and RoHS certified with all levels of PPAP, IMDS and COC documentation.

WAS SHENG has 40 years of experience in CNC machining, milling, multi-stage cold forging, progressive stamping and customized fasteners. Combine international market trend with 30 years manufacture experience, we are proficient in CNC machining, stamping and cold forging parts, our specialist reply instantly from design to produce. By the way, standoff, insert and pin are our famous products.

WAS SHENG has been offering customers precision forging and machining industrial products, both with high-quality manufacturing process and 35 years of experience, WAS SHENG ensures each customer's demands are met.