What should I know before purchasing screws?

Screws come in a variety of shapes and sizes, there are many variations in each of these. Depends on the different material, surface treatment and hardness, also the types of head, thread and drive, it reflects specific mechanical properties.

It's crucial to know what kind of screw you require, below are some tips that should be considered before buying screws.

■ Material and Surface Treatment

Carbon steel is the most widely used material for fasteners industrial applications, but it is may rust and corrode when exposed to moisture. Therefore, there are many surface treatments can apply to prevent rust, galvanization and black phosphating process is common use in fasteners industry. If your screw is automotive parts, they may follow the electroplating specifications standards with automotive industry such as DACROMET, MAGNI or GEOMET.

In response to different application, there are many screws also made from stainless steel, copper and aluminum.

■ Hardness

Hardness is the ability of a material to withstand deformation, which is determined by a standard test where the surface resistance to indentation and abrasion. Generally speaking, screws made from carbon steel will become stronger as the hardness increases and hardness usually correlates approximately with tensile strength in metals. Before choosing screws, hardness is a critical factor you have to consider.

According to ISO 898 mechanical properties of fasteners made by carbon steel and alloy steel, there are many property classes with designations 4.6, 4.8, 5.8, 8.8, 9.8, 10.9 and 12.9. Most used hardness test methods are Brinell, Rockwell and Vickers hardness, each one having a dedicated test way.

In general, we seldom do heat treatment under class 6.8 hardness, it’s belong to low strength screw or bolt with lower cost and low weight load. The most commonly used hardness is class 8.8, 10.9 and 12.9, it’s equal to 22-32 HRC, 32-39 HRC and 39-44 HRC.

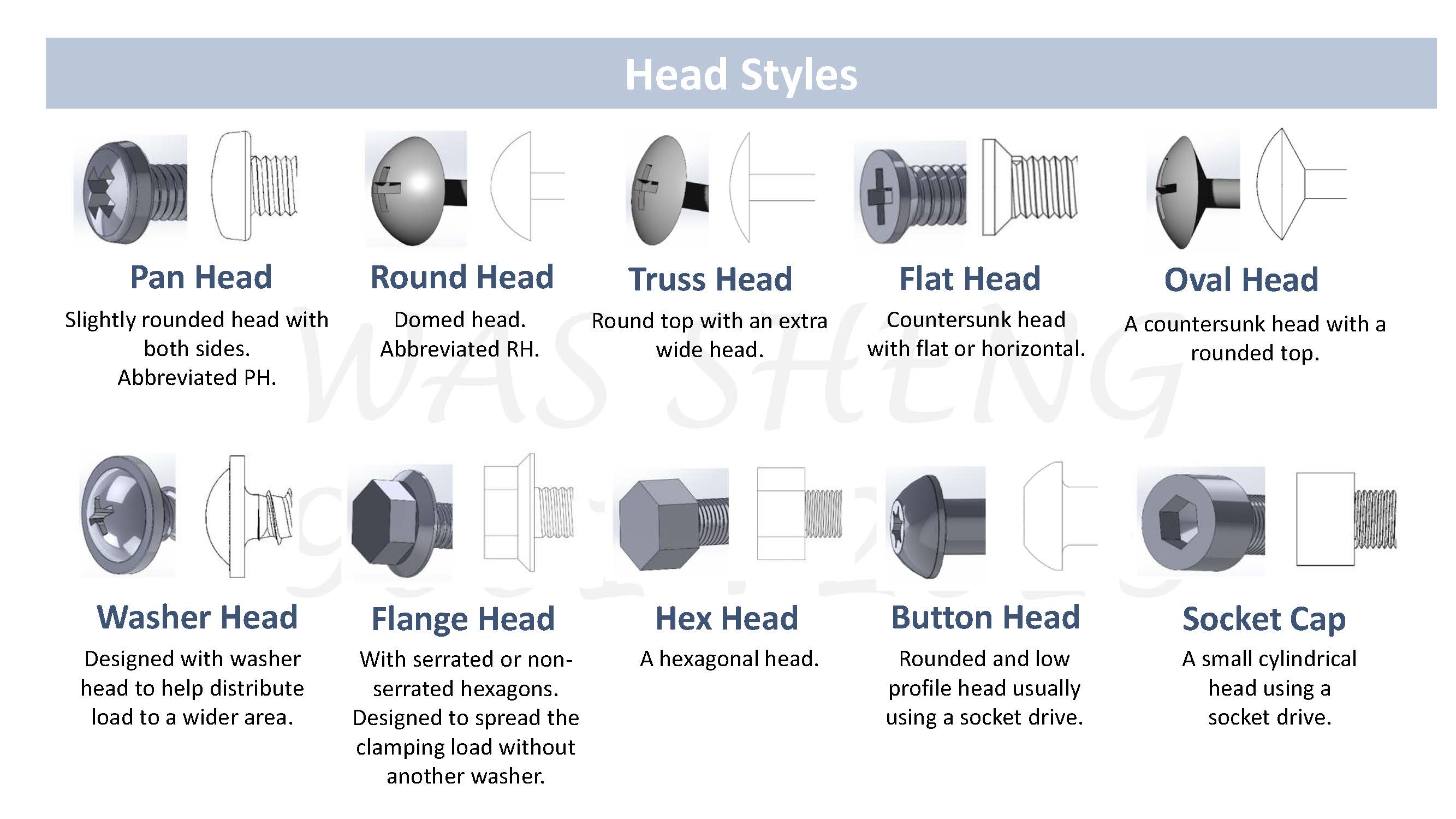

■ Head and Drive Shape

There are so many different screw drives in the world, each provides unique and particular purpose. Below are some different head and drive types for you to consider before designing the fasteners.

-Pan Head

-Round Head

-Truss Head

-Flat / Countersunk Head

-Oval Head

-Washer Head

-Flange

-Hex

-Hex Flange

-Button

-Socket Cap and so on…

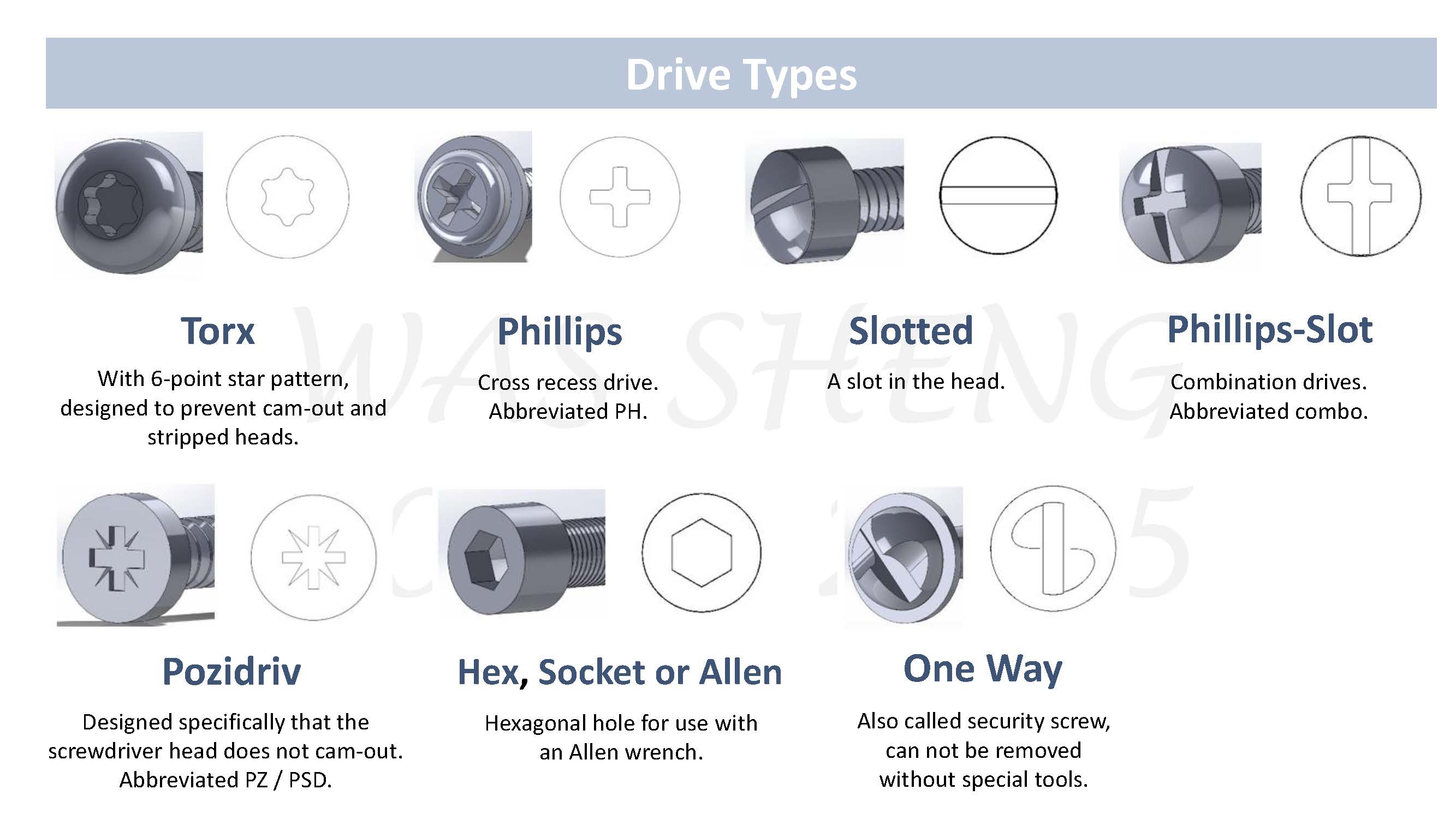

Depends on different drive systems for installation, you must to consider which one you using to force into the workpiece. Screw drives are designed for various applications, including tamper resistant, strength for high-torque, stability during installation, security and universality. The different screw drive types include:

-Torx

-Pin-Torx

-Phillips

-Slotted

-Phillips-Slot

-Pozidriv

-Hex

-One way and so on….

■ Thread

Screw thread is the essential feature of the fasteners, as a helical structure exist on the external or internal cylinder surface. There are three common used thread systems that important to the fasteners:

★ ISO Metric Screw Thread

Metric screw thread is the most commonly used worldwide thread system, according to ISO standard. It defaults with pitch, class, thread direction, major/minor diameter and lead.

Metric threads are descripted by a capital M, followed by the nominal major diameter and pitch in millimeters. For example, M12 x 1.25 mm indicates that the major thread diameter is 12 mm and the pitch is 1.25mm, that means when thread rotation 360°, screw will go ahead with 1.25mm linear distance.

★ UNC / UNF - Unified Inch Screw Threads

Unified inch screw thread series which defined based on the amount of threads per inch and standardized with gauge. Usually followed by the letters UNC and UNF, that means the diameter-pitch combination is from the''coarse'' and ''fine'', it also be followed by the tolerance class.

For those with a diameter smaller than 1/4", screw size is indicated by number (e.g., #10 or No.10), such as #2-56, #4-40, #5-40, #6-32, #8-32 and #10-24. For example, UNC #12-24 screw the number ''12'' is a size with no numerical meaning, by measuring the diameter at slightly less than 7/32″ (5.55 mm) and ''24'' refers to 24 threads per inch.

★ BSW (British Standard Whitworth) / BSF (British Standard Fine) Thread

Same as unified inch screw, defined based on the amount of threads per inch. For example, 1/4’’-20 X 0.5 mm screw means 1/4’’ diameter (.250’’) with 20 threads per inch and length 0.5 mm.