What is Computer Numerical Control (CNC) Machining?

CNC (Computer Numerical Control) machining is a manufacturing process to produce the precision fasteners which require tighter tolerances in all industries. Running on a set of prescribed digital instructions, CNC machines use computer files such as Computer Aided Design (CAD) or Computer Aided Manufacturing (CAM) to execute a project. CNC machining is the common way to create shapes (other method is 3D printing). With high precision method for manufacturing customized fasteners derived from a variety of different materials within tighter tolerances. It’s an indispensable manufacture way across many industries.

This process is suitable for a lot of materials, including stainless steel, carbon steel, aluminum, brass, POM and alloy steel. Main machining processes of CNC machining include Milling, Turning, Drilling.

Turning

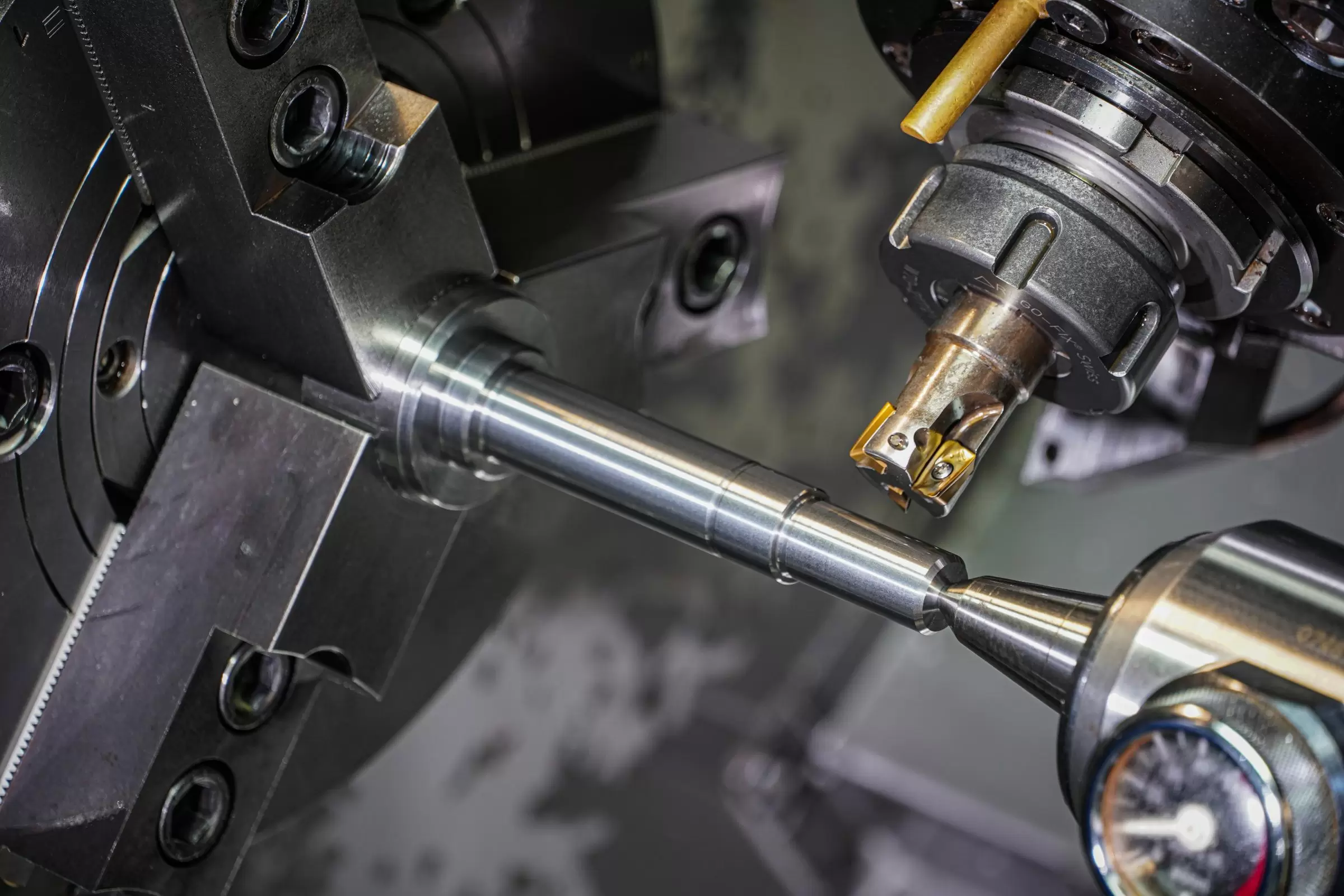

Hold the workpiece in a chuck and place the cutting tool against the spinning piece to create the shape. The axis of rotation in the horizontal or vertical orientation can be taken place in this process. Normally the latter is used for workpiece with a large radius relative to its length.

Milling

Rotating cutters are used to remove material from the workpiece directly. The hardness of the milling tool itself has to be harder than the workpiece being machined. The harder the milling part has, the more difficult it will be to machine, and the less depth it can be machined, so a suitable milling material for machining should be with tough and low hardness.

Drilling

Drilling is one application of turning, rotating cutting tools are used to make round holes in a workpiece. The most important advantage is that it can be combined with other machining operations to make the high precision and tight tolerance holes in various materials from POM to Matel at once.